close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

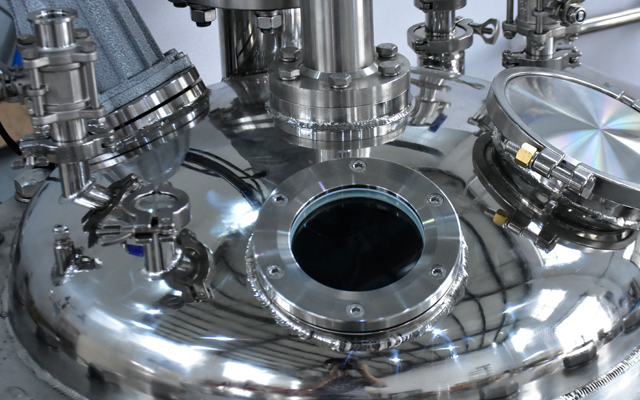

VRR10S

Valuen

For many cases, the boiling points of the components in the mixture will be sufficiently close that Raoult's law must be taken into consideration. Therefore, fractional distillation must be used in order to separate the components by repeated vaporization-condensation cycles within a packed distillation column. This separation, by successive distillations, is also referred to as rectification.

Best Solution for Separating Components of Very Close Boiling Points

High Purity Distillates Can Be Made Through Repeated Distillation in Distillation Column

Various Fractions Can Be Received By Batch or Successive Distillation

| Model | VRR5S | VRR10S |

| Distillation Tank Capacity | 5L / 1.3Gal | 10L / 2.6Gal |

| Collection Tank Capacity | 1L/0.264Gal | 2L / 0.528Gal |

| Collection Tank Quantity | 1-4 pcs (quantity customizable as collected fractions) | |

| Stainless Steel Material | Sanitary Grade 304 Stainless Steel (Optional: Stainless Steel 316) | |

| Heating for the Tank | Oil Bath Heater | |

| Distillation Column Height | Height customized as required theoretical plates quantity | |

| Distillation Column Diameter | 40mm, 50mm or other customizable size | |

| Heating for the Distillation Column (Optional) | Heating Jacket or Heating Tape | |

| Strring Mode | Magnetic Stirring via Magnetic Rotary or Top Head Stirrer (Magnetic or Mechnical Sealing) | |

| Working Temperature Range | Room Temperature to 300°C | |

| Control System | Digital Display Stirring speed controller, Time controller of reflux-receving dispenser, Heating temperature controller for heating jacket or tape, Heating temperature controller if tank heated by oil bath | |

| Utilities (Optional) | Cooling Circulator for Condenser, Vacuum Pump | |

| Power Supply | 220V, 50/60Hz, Single Phase; 220V or 380V, 50/60HZ, 3 Phase | |