close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

VJR100S(D)

Valuen

Jacketed Stainless Steel Vacuum Mixing/ Emulsion/Dispersion/Synthesis Reactor

Mixing/Emulsification/Homogenization/Dispersion, Herbal Extraction, Synthesis, Decarboxylation, Concentration, Solvent Recovery

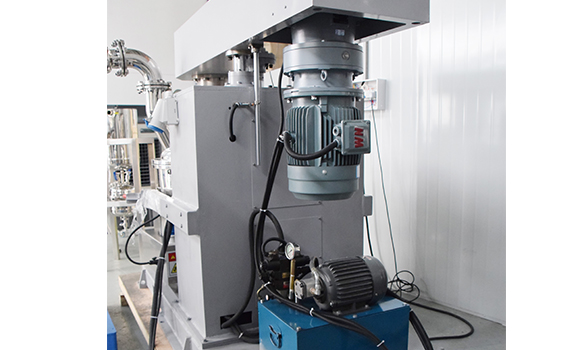

Equipped With Hydraulic Lift Device, Allowing Flexible Lifting Of Cover And Stirring Paddle

Liftable Design Facilitates Convenient Discharging, Handling, Cleaning, And Maintenance

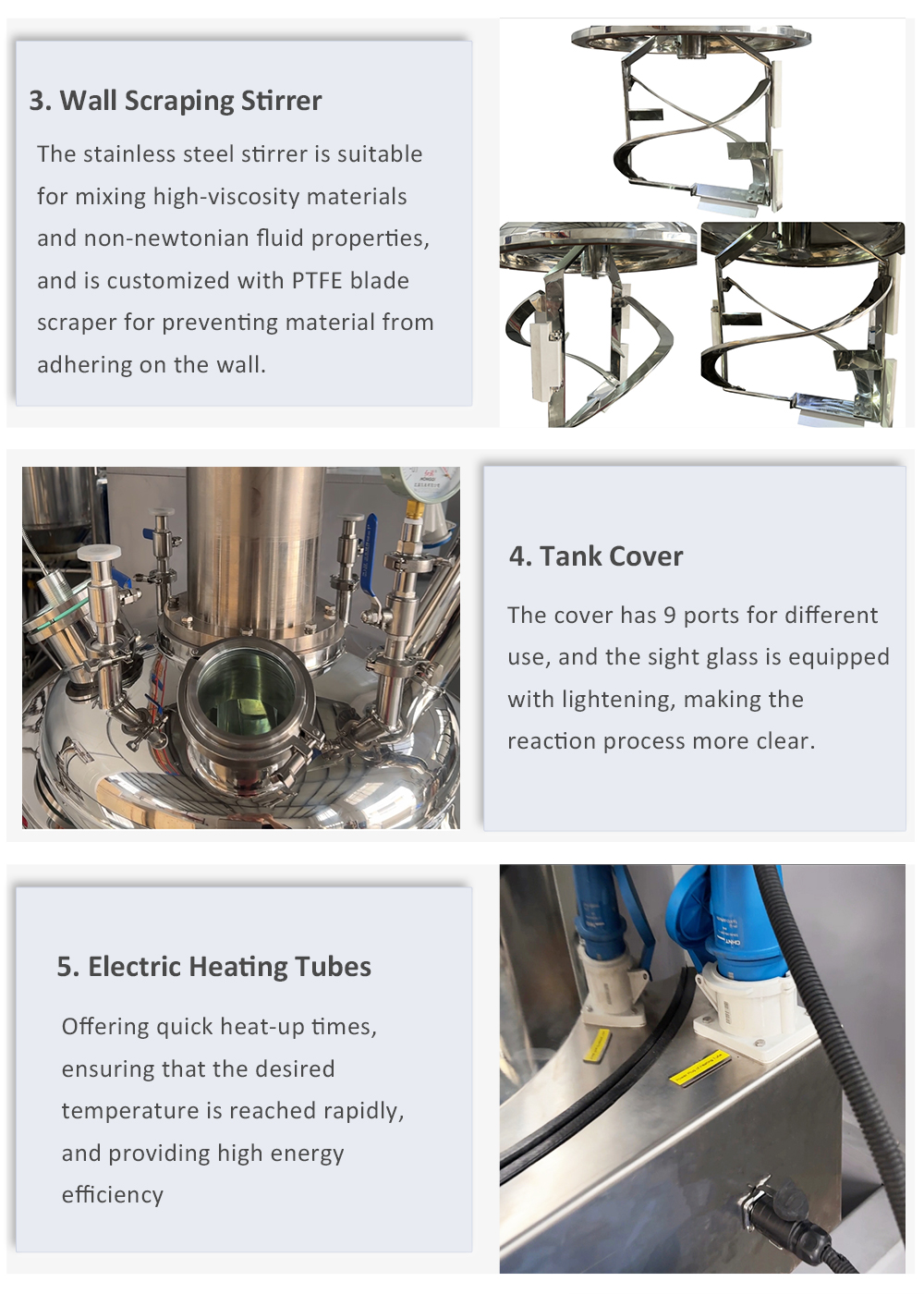

Tank Body Is Precisely Machined To Enable The Stirring Paddle To Fully Scrape The Walls, Making It Suitable For Mixing High-Viscosity Materials And Non-Newtonian Fluid Properties.

| Jacketed Reaction & Mixing Tank | Reaction Tank Capacity | 100L/ 150L/ 200L (High precision tank after lathe machining) |

| Material | Stainless Steel 304 for Parts in Contact with Material | |

| Lid Material | Stainless Steel 304 (Optional: SS316) | |

| Ports on Lid | Powder adding port, liquid feeding port, 2 sight glasses; a vacuum port; and temperature sensor port, condenser port (optional) | |

| Ports on Reaction Tank | Circulation inlet/outlet ports | |

| Wheels quantity | 4pcs | |

| Stirrer with PTFE Scraper | Stirrer Material | Stainless Steel 304 (Optional: SS316) |

| Stirring Shaft Material | Stainless Steel 304 (Optional: SS316) | |

| Wall Scarping Bracket | Stainless Steel 304 (Optional: SS316) | |

| Wall Scraping Blades | PTFE | |

| Stirring Speed of Stirring Paddles and Scraper | 0~90 rpm(adjustable) | |

| Stirring Motor Power | 4.5KW/ 5.5KW/ 6.5KW, 380V/50HZ | |

| Lift of Reactor Lid | Lifting Method | Hydraulic lifting beam type |

| Material | Carbon steel for high rigidity structure, sprayed with high-grade paint | |

| Lifting Distance | ≤650mm | |

| Condenser (Verticalble and Horizontalable) | Condeser type | Coils condenser |

| Cooling area | 1m² | |

| Material | Stainless Steel 304 (Optional: SS316) | |

| Non-jacket Receiving Tank | Tank Volume | 20L/50L/100L |

| Ports on Tank | Vacuum port, Spare port and Drain port | |

| Material | Stainless Steel 304 (Optional: SS316) | |

| Electric Heating Tubes | Heating Power | 9KW |